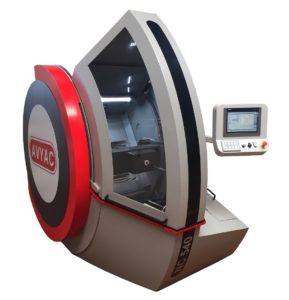

Product details

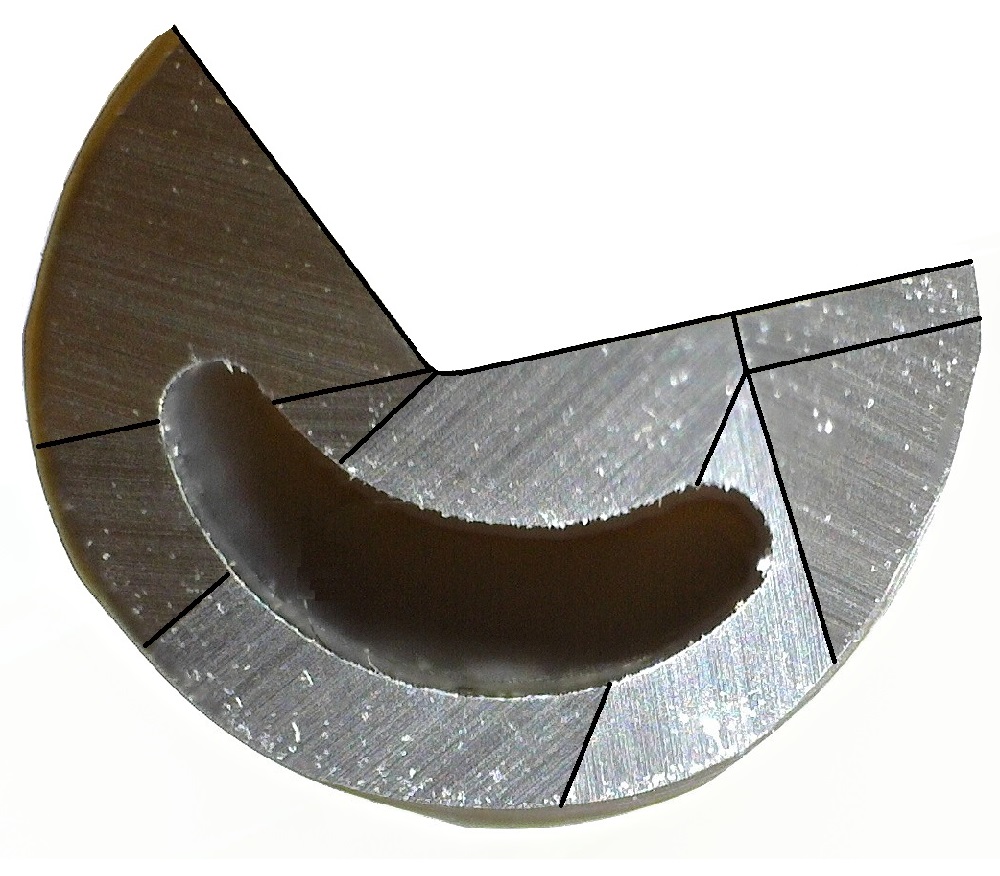

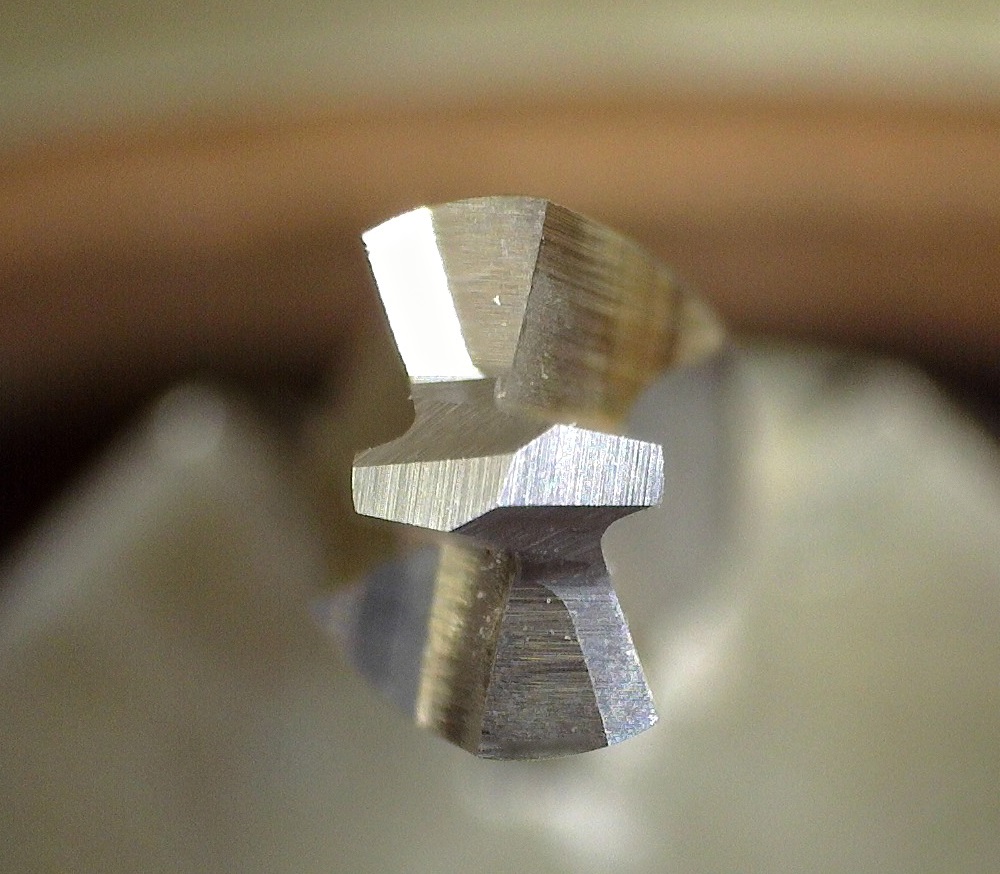

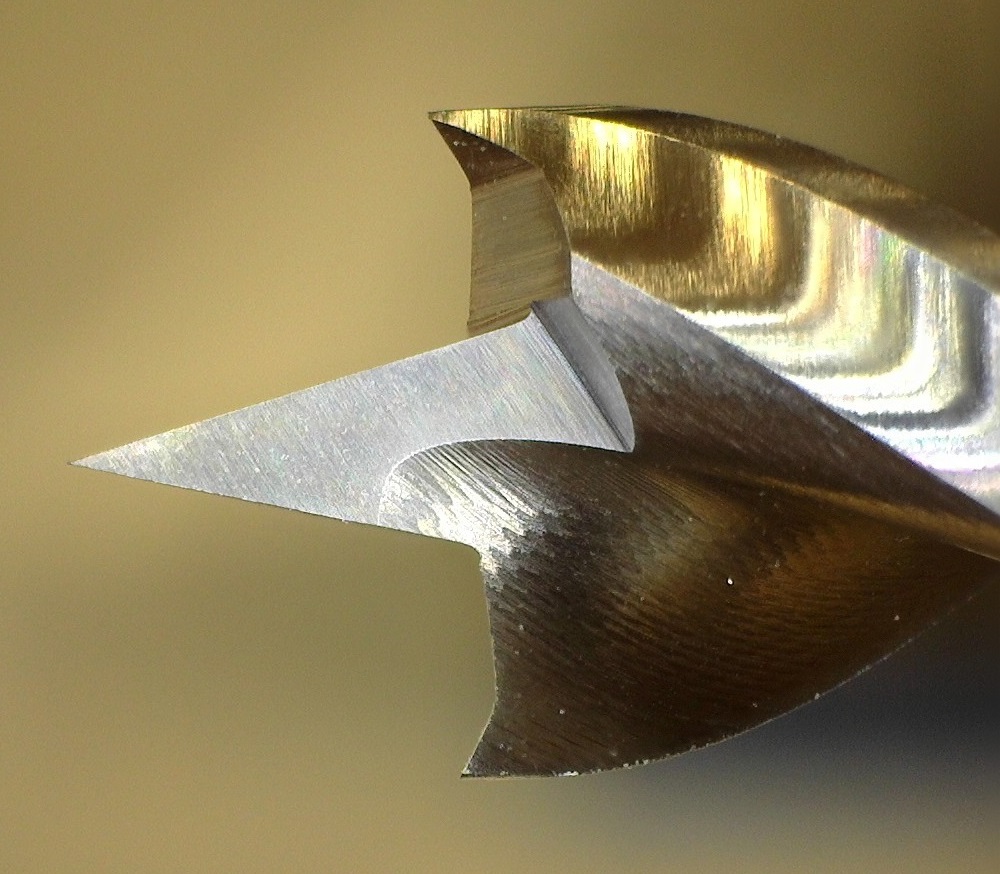

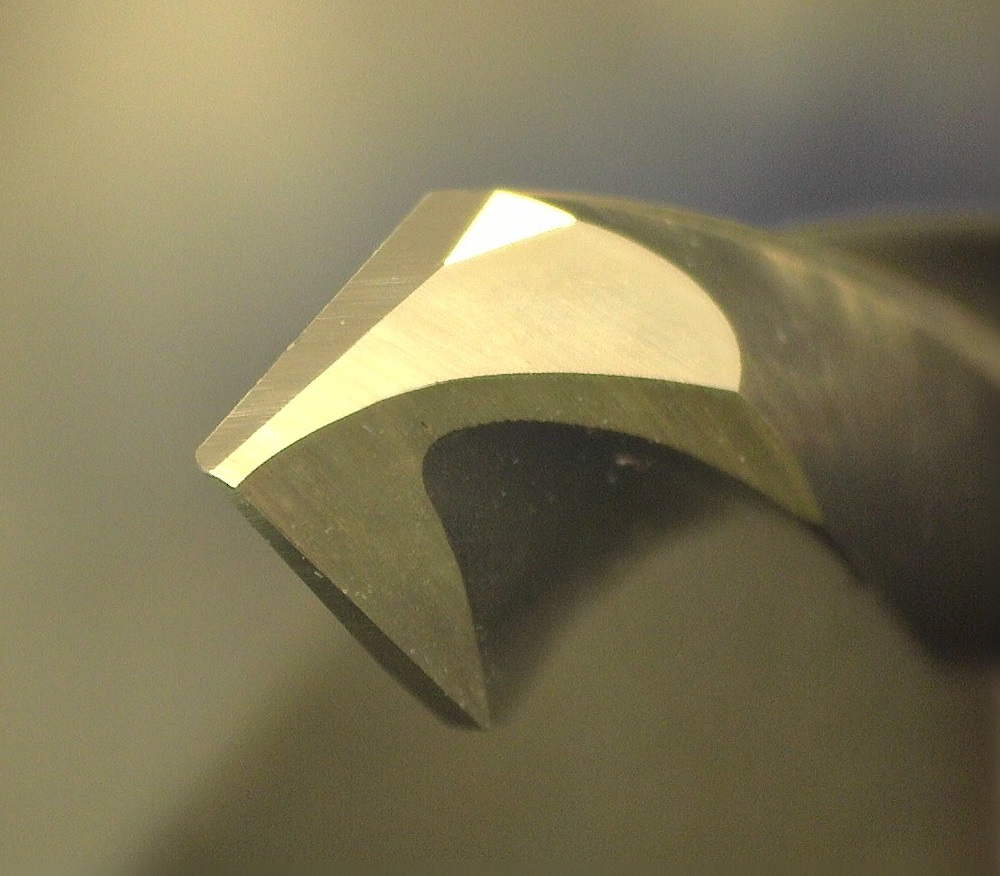

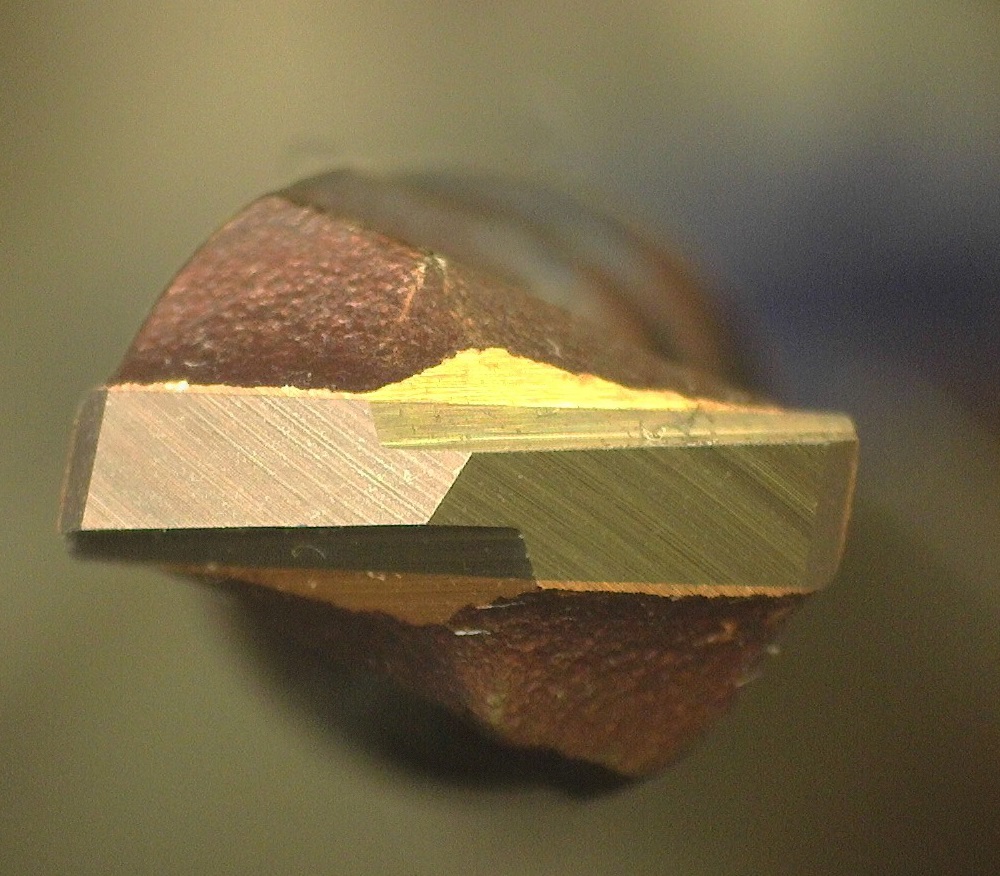

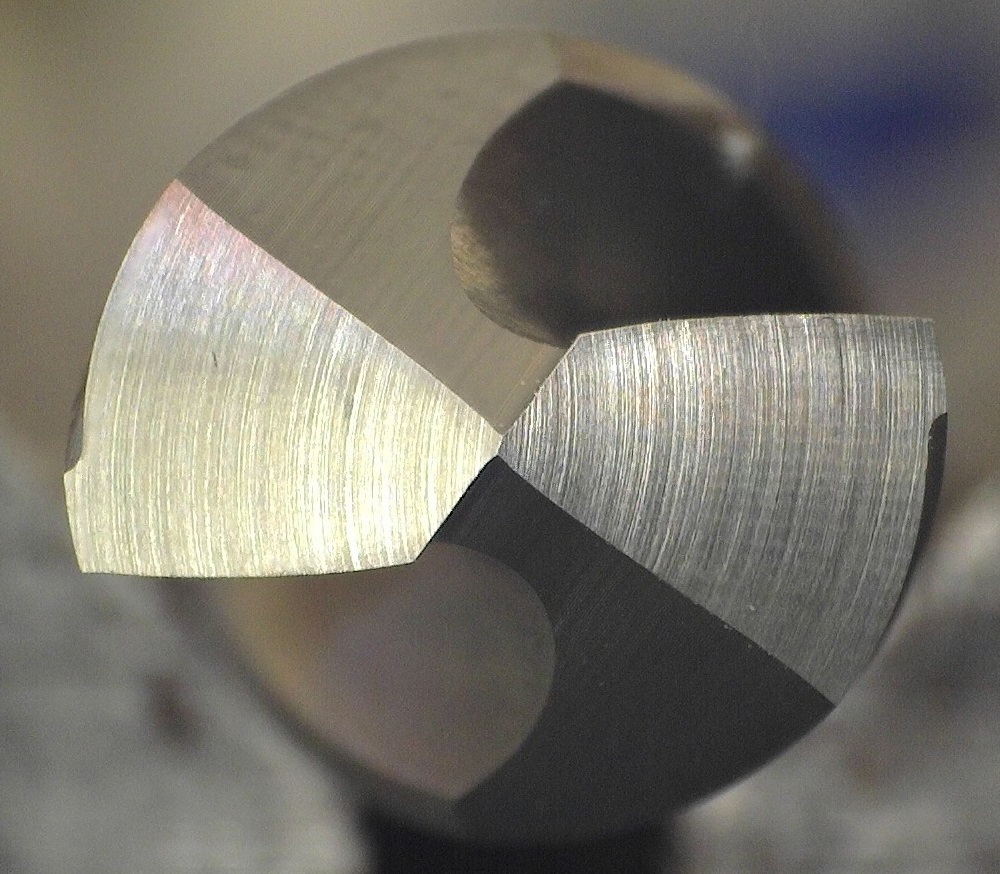

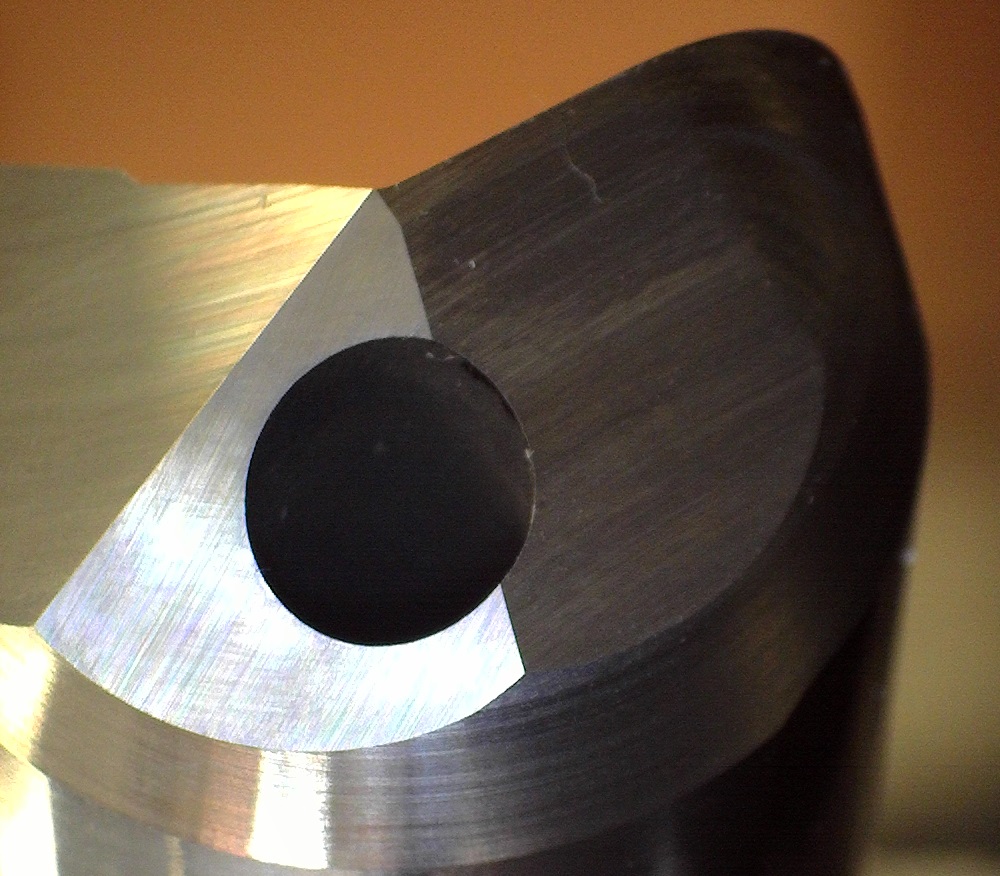

The NC540 offers you a unique solution with a modern fairing for sharpening your large drill bits. Highly stable, it will ensure the production and sharpening of your HSS / Carbide drills with a wide variety of sharpening geometries, such as conical relief, facets, web thinning, second point angle, steps…

- Robust design : Designed for long tools, it stands out for its stability, repeatability and sharpening precision

- Intuitive, touchscreen, plug and play : Quick setup, pre-configured programs developed in-house, short operator training

- Optimised floor footprint : The design was chosen to accommodate the tool's movement during sharpening

- Fully automatic : economical circular loader with up to 90 tools, for serial ou differentiated programs

- Great versatility : Small and large diameters, drill bits of any length and numerous sharpening services provided: drill bits, milling cutters, deep holes Gundrills, punches, reaming drill bits, flat bottom drill bits, engraving tools, taps...

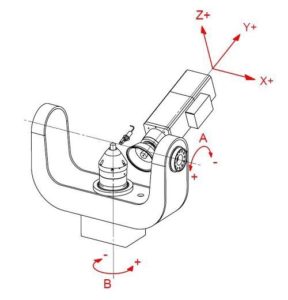

Technical specifications

Dimensions (W x D x H)

2200 x 1600 x 2600 mm (7’3″ x 5’3″ x 8’3″)

Weight

2000 Kg (4400 lb)

Grinded drills dimensions

Ø 5 to 40mm (0.2″-15.75″) – max. length: standard 1000mm (39″) – Optional 2000mm (78″)

Spindle performance

ISO 30 cone or HSK 63– power 4.5 kW – max. 12000 rpm

Pneumatic clamping

Accuracy collets W25, collets with double cones or 6 jaws mandrel

Grinding wheels

Ø 100 to Ø 150 – CBN or diamond – Wheel holder setup up to 3 wheels together

Cooling system

Flow rate 50-90 l / min, grinding oil or emulsion

CNC Control

SIEMENS Sinumerik 840D SL with touch screen and motors with absolute encoders

Tool detection

3D Marposs sensor

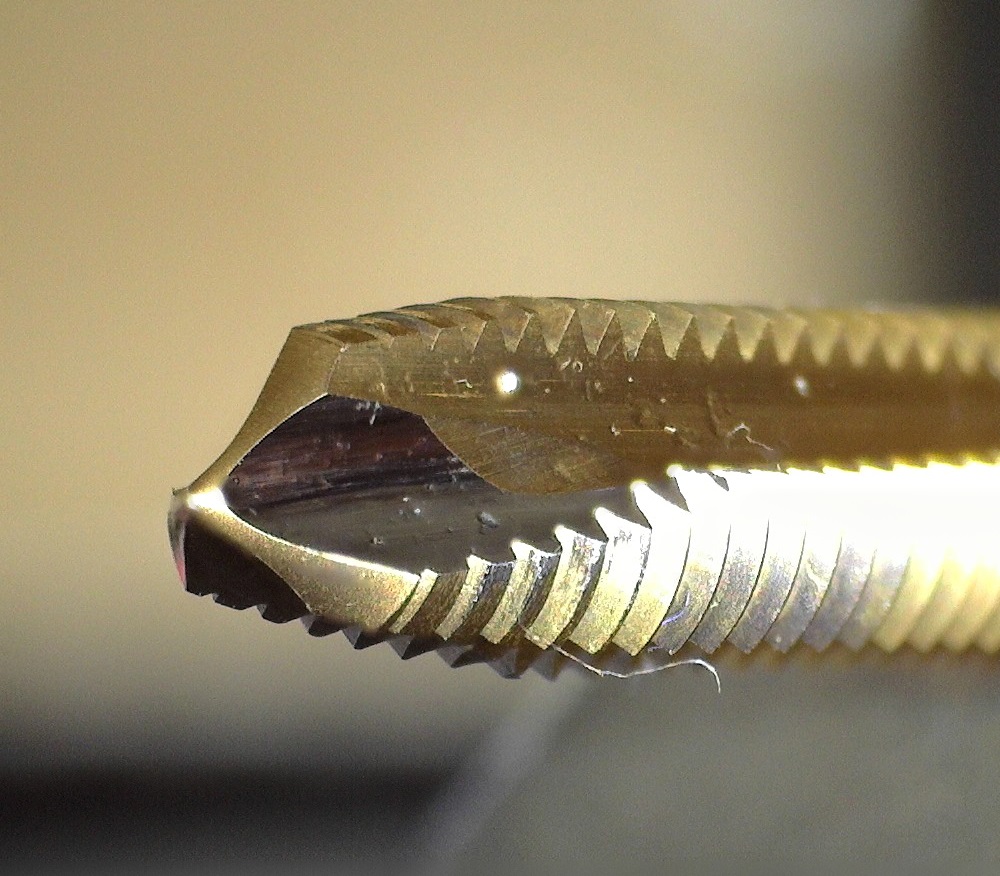

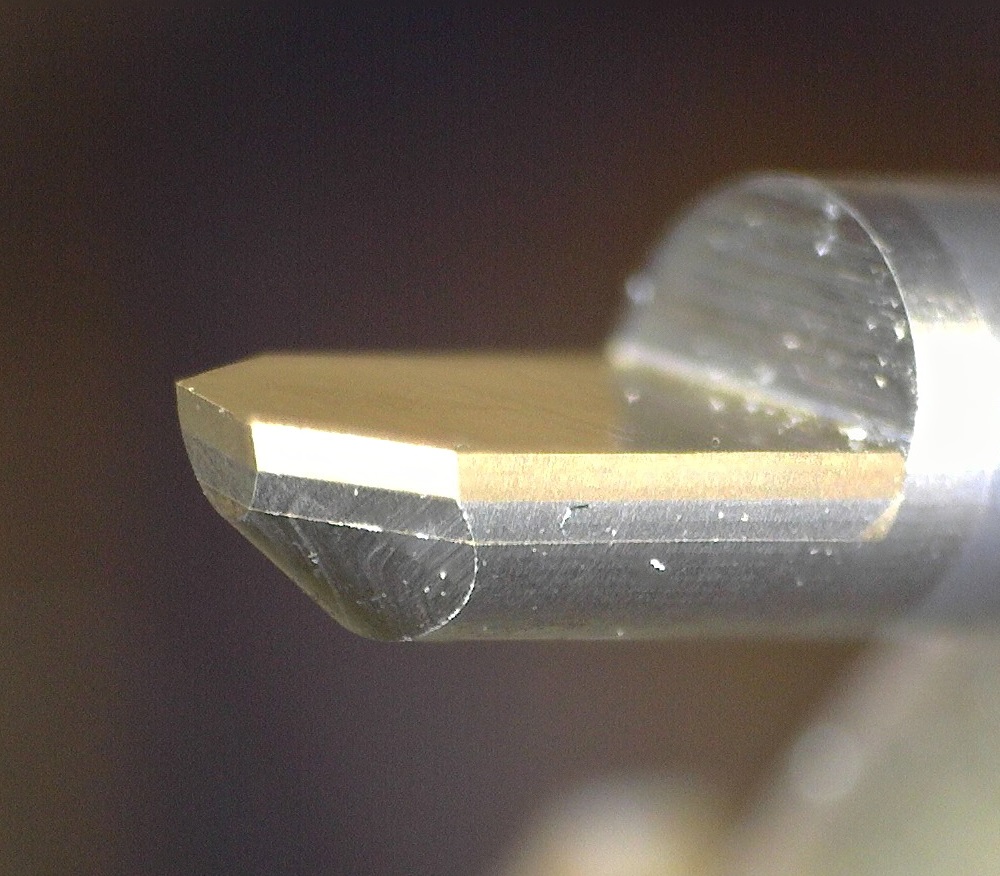

Right-hand helix twist drills with conical or facets relief, gundrill bits for deep holes drilling with 1 or 2 flutes, metal sheet drills, step drills, flat bottom drill bits, brad point, woodworking drill, reamer, end mills with 1, 2, 3 or 4-flutes, countersinks, taps, engraving tools, punches… Contact us for feasibility studies.